The Great Appliance Move: How to Safely Transport Your Machines Without Breaking Them (Or Your Back)

Thinking about relocating your beloved appliances but worried about the risks involved? This comprehensive guide covers everything you need to know about moving appliances safely, from essential preparation steps to professional techniques that protect both your machines and your body.

Moving day can be stressful enough without worrying about your expensive appliances getting damaged or throwing out your back in the process. Whether you’re relocating across town or across the country, your refrigerator, washing machine, and other household workhorses need special care to arrive at their new home in perfect working condition. The good news is that with proper planning, the right equipment, and smart techniques, you can successfully move even the heaviest appliances without breaking a sweat – or breaking the bank on repairs.

Most people underestimate just how complex appliance moving can be. These machines aren’t just heavy; they’re filled with delicate components, fluids, and moving parts that can easily be damaged during transport. From refrigerant systems that need time to settle to washing machine drums that require special stabilization, each appliance has its own unique moving requirements. Add in the physical challenge of maneuvering 300-pound refrigerators through doorways and down stairs, and it’s easy to see why so many DIY moves end in disaster.

This guide will walk you through every aspect of safe appliance transportation, from the initial planning stages to the final setup in your new home. We’ll cover the essential tools you’ll need, step-by-step moving procedures for different appliance types, and crucial safety techniques that protect both you and your machines. Whether you decide to tackle the job yourself or hire professionals, you’ll have all the knowledge needed to make informed decisions and ensure a successful move.

Key Outtakes:

- Start your appliance preparation 24-48 hours before moving day to prevent damage and ensure proper disconnection

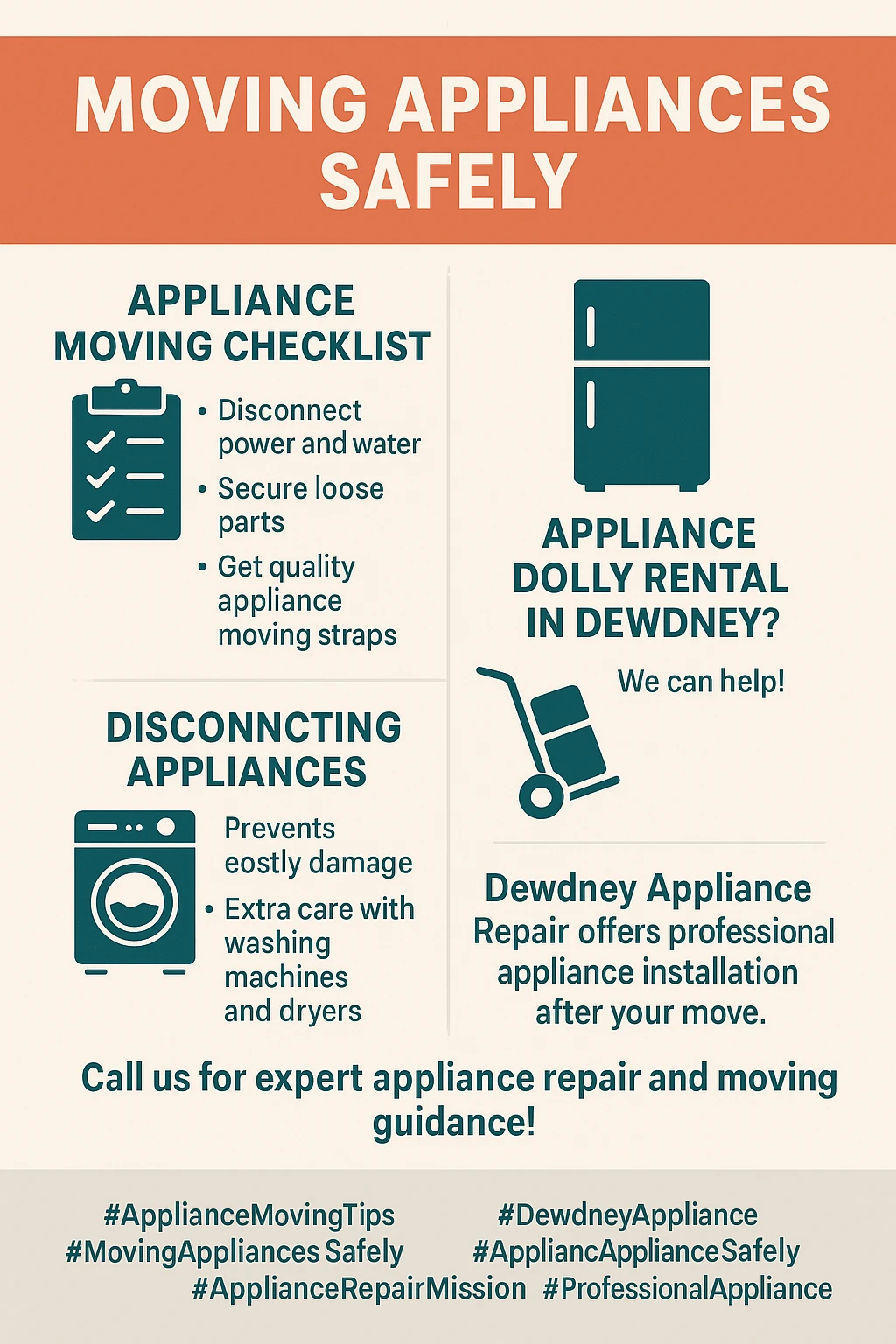

- Use specialized equipment like appliance dollies and moving straps to reduce injury risk and protect your machines

- Each appliance type requires specific handling techniques, from refrigerator settling periods to washing machine drum stabilization

- Professional services provide insurance coverage and expertise that often justify the additional cost for complex or valuable appliances

- Post-move setup requires patience and proper procedures to ensure optimal performance in your new home

Planning Your Appliance Move Like a Pro

The key to a successful appliance move starts long before you touch a single machine. Professional movers know that proper planning can prevent up to 80% of appliance damage during transport, which is why they always begin with a comprehensive assessment. This isn’t just about knowing what you’re moving – it’s about understanding the unique challenges each appliance presents and preparing accordingly.

Start by creating a detailed inventory of all the appliances you plan to move. Walk through your home and document everything from your main kitchen appliances to that extra freezer in the garage. Take photos from multiple angles, noting any existing damage or wear. This documentation serves two important purposes: it helps you track potential damage during the move, and it provides valuable information for insurance claims if something goes wrong. Don’t forget to record model numbers and approximate ages, as older appliances may require different handling techniques.

Timing becomes crucial when you’re dealing with appliances that need special preparation. Refrigerators and freezers require at least 24 hours of defrosting time, and this process can’t be rushed without risking water damage during transport. Washing machines need their final cleaning cycle completed 2-3 days before moving to allow proper drying and prevent mold growth during transit. Mark these deadlines clearly on your moving calendar and set reminders – there’s nothing worse than realizing your freezer is still full of ice on moving day.

The physical logistics of your move require careful measurement and route planning. That beautiful French door refrigerator might fit perfectly in your current kitchen, but will it make it through your new home’s narrow hallway? Measure not just the appliances themselves, but also their clearance requirements for doors, turns, and stairs. Professional movers often need to remove refrigerator doors to navigate tight spaces, so factor this possibility into your planning.

Don’t overlook the utility disconnection requirements, as this is where many DIY moves run into trouble. Gas appliances require licensed professionals for safe disconnection in most areas, and this service needs to be scheduled well in advance. Water lines, electrical connections, and built-in installations all have their own requirements and timelines. Create a master schedule that coordinates all these moving parts, and always build in buffer time for unexpected complications.

Essential Equipment and Tools for Safe Moving

Having the right equipment can mean the difference between a smooth move and a trip to the emergency room. While it might be tempting to improvise with whatever you have on hand, appliance moving requires specialized tools designed to handle extreme weights and awkward shapes safely. The good news is that most of this equipment is readily available for rent, making professional-grade tools accessible for DIY movers.

The appliance dolly is your most important tool, and not all dollies are created equal. Heavy-duty appliance dollies can support up to 800 pounds and feature wide bases with multiple wheels for stability. These aren’t the same as regular furniture dollies – they’re specifically designed with straps and secure platforms to handle the unique challenges of appliances. Hand trucks work well for some situations, especially stairs, but dollies provide better stability and control for most appliance types.

Moving straps and securing systems can dramatically reduce the physical strain of appliance moving. Shoulder dolly straps distribute weight across your stronger muscle groups and can reduce lifting strain by up to 50% compared to manual lifting. These systems work by using leverage and proper body mechanics to make heavy loads more manageable. However, they require proper training and coordination between team members – don’t attempt to use them without understanding the correct techniques.

Protective materials are essential for preventing cosmetic damage that can be just as costly as mechanical problems. Moving blankets provide cushioning against impacts and prevent scratches on both appliances and walls. Bubble wrap works well for smaller components and delicate trim pieces, while foam corner protectors shield vulnerable edges. Don’t forget plastic wrap and tape for securing doors, drawers, and loose components during transport.

Floor protection might seem like an afterthought, but damage to your floors can be more expensive than appliance repairs. Furniture sliders allow you to glide heavy appliances across surfaces without scratching, but different floor types require different materials. Hard plastic sliders work on carpet, while felt-bottomed versions protect hardwood and tile. For particularly heavy appliances or delicate floors, consider laying down sheets of plywood or hardboard to distribute weight and prevent damage.

Appliance-Specific Moving Strategies

Each type of appliance presents its own unique challenges, and understanding these differences is crucial for preventing damage during your move. What works perfectly for a dishwasher could spell disaster for a refrigerator, so it’s important to tailor your approach to each machine’s specific requirements and vulnerabilities.

Refrigerators are perhaps the most challenging appliances to move safely, primarily because of their cooling systems and the risk of coolant damage. The golden rule for refrigerator moving is to keep the unit upright whenever possible. If a refrigerator must be tilted, never exceed a 45-degree angle, and the unit must remain off for 24-48 hours after transport to allow the refrigerant to settle properly. The defrosting process requires careful attention to drainage, and many people underestimate how much water can accumulate – have plenty of towels ready and protect your floors.

Washing machines require special attention to their internal drum systems, which can be severely damaged if not properly secured during transport. The factory shipping bolts that held the drum in place during initial delivery are crucial for moving – without them, the drum can bang around inside the machine and cause thousands of dollars in damage. If you’ve lost the original bolts, replacement kits are available from manufacturers, or you can carefully pack foam around the drum to minimize movement. Never move a washing machine without some form of drum stabilization.

Dryers present their own set